When it comes to home maintenance, one often overlooked aspect is the dryer duct system. Not only is proper dryer venting crucial for the efficiency of your appliance, but it’s also a matter of safety. In this article, we’ll explore the importance of having dryer ducts that are up to code and how a metal recessed dryer vent box can contribute to a safer, more efficient home.

The passageway of dryer exhaust duct terminals shall be undiminished in size and shall provide an open area of not less than 12.5 square inches (8065 mm2).

Why is this important? Terminations with smaller passageways can reduce energy efficiency and create back pressure, leading to accelerated buildup.

The new code mandates that the conduit through the termination hood must not diminish in size and must maintain at least 12.5 square inches of area.

Why Dryer Duct Compliance Matters

Dryer fires are a real and dangerous risk in households, often caused by lint accumulation and improper venting. To mitigate these risks, building codes set standards for the installation and maintenance of dryer ducts. Adhering to these codes not only protects your home from potential fire hazards but also ensures your dryer operates efficiently.

Download Brochure

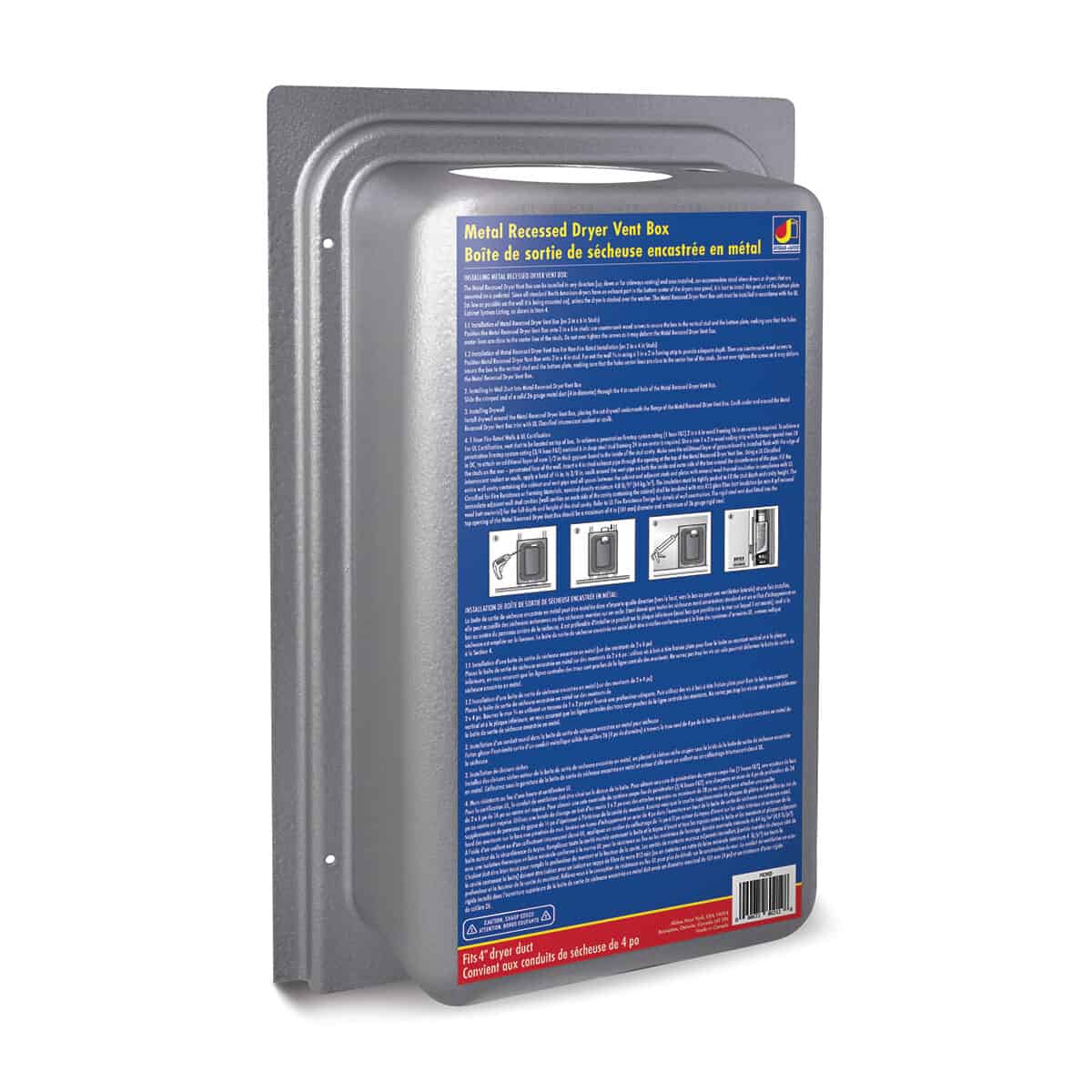

A metal recessed dryer vent box offers several advantages that align with building codes and enhance the safety and functionality of your laundry system:

In the United States, the International Residential Code (IRC) M1502.3.1 Exhaust termination outlet and passageway size is the primary reference for home inspectors when evaluating dryer venting. This code outlines specific requirements for duct material, length, and routing.

The passageway of dryer exhaust duct terminals shall be undiminished in size and shall provide an open area of not less than 12.5 square inches (8065 mm2).

Understanding Codes and Standards

Both the IRC and IMC emphasize the importance of following the manufacturer’s guidelines for vent lengths, diameters, and the number of turns. This is because each dryer model may have unique airflow needs, and adhering to the manufacturer’s specifications ensures optimal performance and safety.

To determine if your dryer ducts meet the current standards, consider the following checklist:

1502.3.1 Exhaust termination outlet and passageway size.

The passageway of dryer exhaust duct terminals shall be undiminished in size and shall provide an open area of not less than 12.5 square inches (8065 mm2).

Material: Dryer ducts should be made of rigid or semi-rigid metal to resist crushing and lint accumulation.

Length: The total length of the duct should not exceed the manufacturer’s recommendation, and each 90-degree turn typically reduces the allowable length by 5 feet.

Routing: Ducts should vent directly to the outside, not into attics or crawl spaces, to properly expel moisture and lint.

Termination: The outside vent should have a backdraft damper (and no screens) to prevent outside air from entering and to keep pests out.

Conclusion

Proper dryer duct installation and maintenance are key to preventing fires and maintaining the efficiency of your appliance. By choosing a metal recessed dryer vent box and ensuring your system adheres to the IRC and IMC codes, you can have peace of mind knowing your dryer ducts are up to standard. Remember, safety in your home starts with attention to detail and compliance with building codes.

Take action now to review the new building code requirements and make any necessary adjustments to your construction practices. Your reputation and success in the industry depend on it!

In the construction and home inspection industry within the United States, compliance with the International Residential Code (IRC) M1502 is standard practice for the installation of dryer venting systems. It’s important to note that while the IRC provides a baseline, certain states may enforce additional or more stringent regulations.

For comprehensive specifications on clothes dryer venting, professionals also reference the International Mechanical Code (IMC) 504. This code covers a broader scope of mechanical requirements, including those pertinent to clothes dryers.

It’s critical for contractors to recognize that both the IRC and IMC offer guidelines that ultimately defer to the specifications provided by the dryer manufacturer regarding vent lengths, diameters, and the permissible number of turns. Adhering to these manufacturer guidelines is essential for ensuring optimal dryer performance and maintaining code compliance.